Bindex Digital

Bindex Digital

SEAMLESSLY SECURE YOUR SUCCESS WITH EVERY BIND!

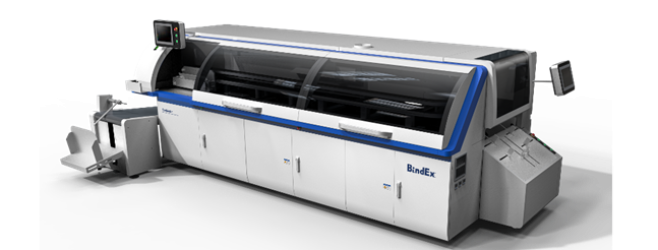

ECOBINDER is a fully automated five-clamps perfect binder. Except for the cover size which needs to be manually entered on the touch screen, the book thickness data is automatically collected by the automatic thickness measuring device. It is an ideal equipment for flexible and quick binding of small and medium book quantities.

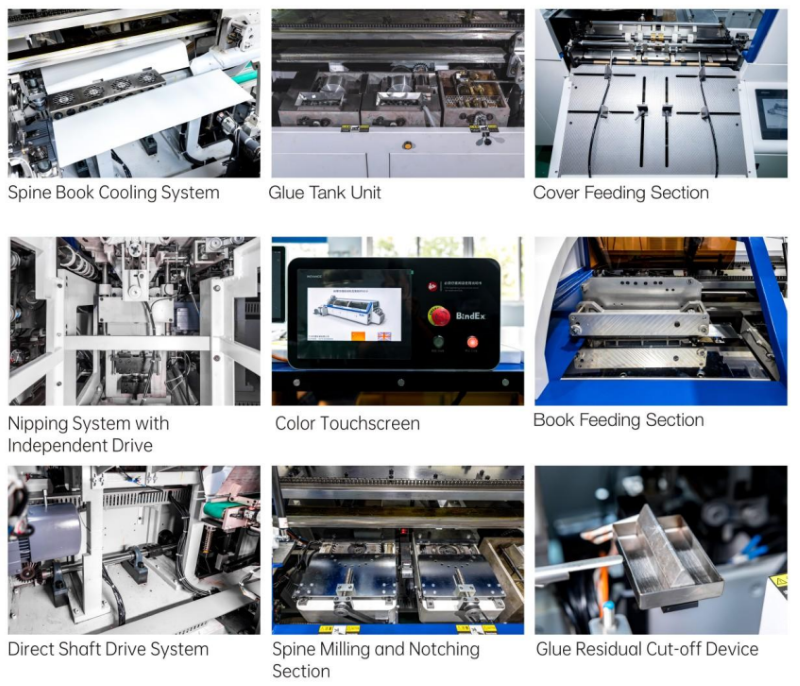

Common Technical Features:

- Automatic thickness measuring device.

- Book clamps, opening and closing automatic adjustment.

- Professional independent notching section for superior spine preparation, width automatic adjustment.

- Double Spine glue units with independent temperature control; And It is automatic spine glue cut-off; Option: PUR glue unit.

- Side glue section, width automatic adjustment.

- Cover guides/scoring on the cover feeding section, width automatic adjustment.

- Cover guides(both front and side) on the nipping section, width automatic adjustment; Heavy duty double cam mechanism for superior spine nipping quality.

- Book positioning guides, automatic adjustment.

- Delivery channel, width automatic adjustment.

- Integral casting and strong rigidity.

- Option: BindEx cloud platform, to track machine OEE and productivity and realize smart industry 4.0.

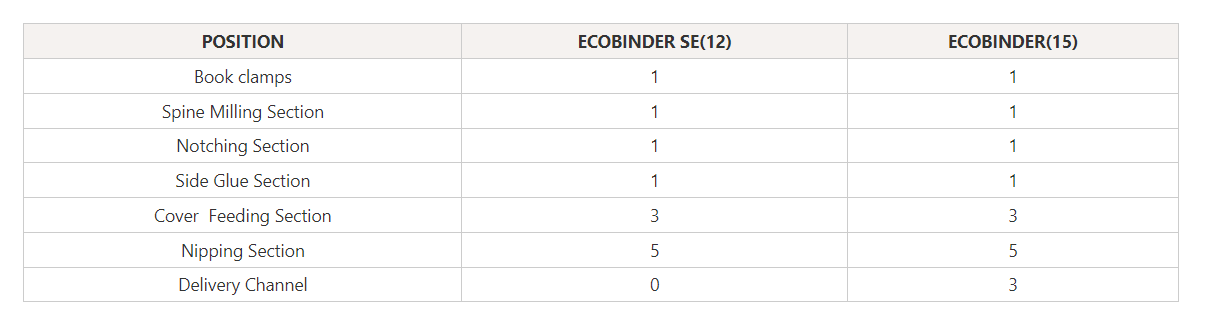

MAIN DIFFERENCE:

ECOBINDER: Automatic book collecting section to ensure high quality book spine formation; and realize single person operation. Front book delivery: For single person front operation and maintenance (OPTION)

SERVO-POINT DISTRIBUTION TABLE

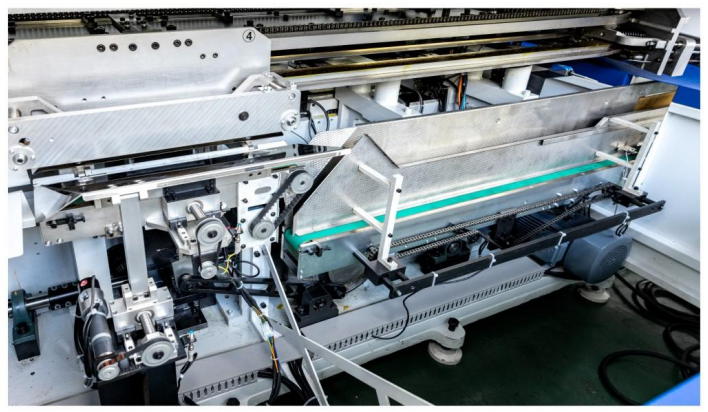

ECOBINDER is equipped with an automatic book delivery to ensure that the book falls smoothly from the clamp; it also can connect to the digital three knife trimmer, forming a digital perfect binding line to meet various production need.

ECOBINDER DIGITAL PERFECT BINDING LINE

ECOBINDER can connect to BindEx's BOSSA 50e digital three knife trimmer, forming a digital perfect binding line to meet various production needs.

SPECIFICATION

|

Clamps |

5 |

|

Max. Mechanical Speed |

2000 (c/h) |

|

Max. Binding Size |

450×320(mm) |

|

Min. Binding Size |

140×120 (mm) |

|

Max. Cover Size |

450×610 (mm) |

|

Binding Thickness |

2-50 (mm) |

|

Net Weight |

4000 (kg) |

|

Main Power |

20 (kw) |

|

Overall Dimensions(L*W*H) |

4400×1950×1650 (mm) |

EXPLORE PERFECT BINDER

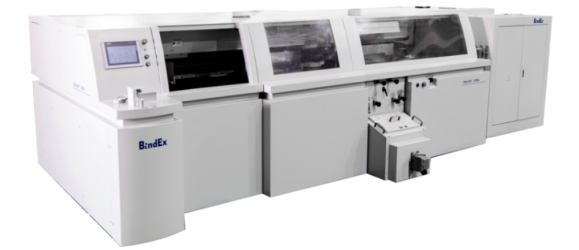

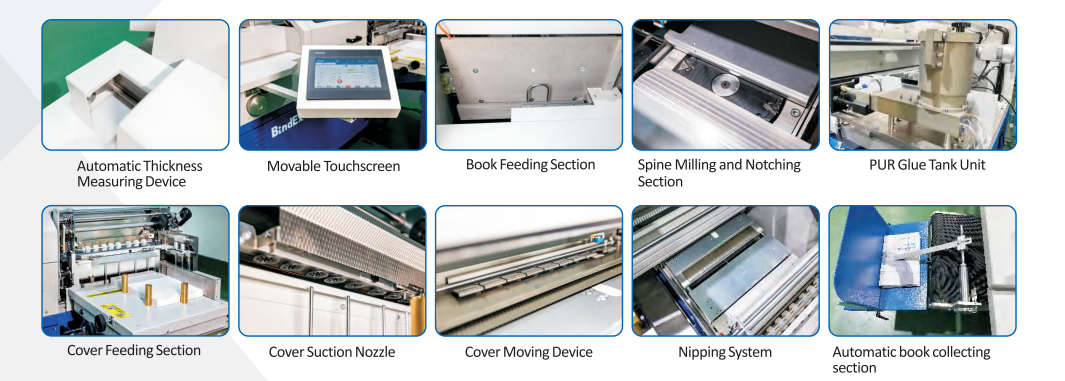

EXPLORE Perfect Binder is an innovative fully automatic PUR/EVA solution that adapts to various requirements of short-run binding, long-run binding, and on-demand book printing. The EXPLORE model features easy operation, rapid format conversion, and low maintenance service costs. This machine can be equipped with either a patented PUR glue nozzle system or an EVA adhesive system. The PUR glue nozzle system consists of a built-in preheated pressure glue pot with a capacity of 2KG and a nozzle capable of applying spine glue and side glues simultaneously. The use of the built-in enclosed glue nozzle system sets the Explorer model apart from others.

Technical Features

Utilizes a movable touchscreen for convenient single-person operation.

Compact single-clamp layout saves space.

Data acquisition: with automatic thickness measurement device. Each station of the machine can be automatically adjusted according to the thickness measurement data by servo motor.

Book feeding platform: Equipped with vibration function to aid in align book blocks.

Book clamp: Automatically adjusts opening width based on thickness measurement data.

Spine Milling and Notching device: Maximum milling/grooving depth of 2mm ensures glue penetration, effectively preventing bottoming out, suitable for various types of book blocks; equipped with a dedicated cam mechanism to achieve overall lowering of the milling/grooving station for processing sewn book blocks.

Glue system can choose between PUR or EVA:

PUR: Applies side and bottom glues simultaneously, equipped with a 2kg pressure glue pot and automatic glue cutoff function.

EVA: Intelligent adhesive system with automatic glue cutoff for both bottom and side glues, automatic adjustment of glue roller and glue bar height.

Covering feeding system: Equipped with automatic covering system, capable of stacking covers up to 85mm high, suitable for cover materials ranging from 80-300g/sqm, with die-cutting pressure line mechanism; the direction of pressure lines can be switched on the touchscreen as per requirement; creasing of cover flaps is also achievable.

Nipping system: Adjustable clamping time ensures high-quality formation of book spines.

Book collection device: Equipped with automatic lifting book collection table to reduce workload for operators.

Interconnection: Equipped with data collection box for bidirectional data exchange, facilitating cloud-based equipment, remote operation, and supporting smart factory construction.

SPECIFICATION

| Clamps | 1 |

| Max. Mechanical Speed | 500c/h |

| Max. Binding Size | 410mm*310mm |

| Min. Binding Size | 135mm*105mm |

| Max. Cover Size | 680mm×415mm |

| Min. Cover Size | 240mm×130mm |

| Binding Thickness | 3mm-50mm |

| Cover Weight | 80-300 |

| Max. Cover Stacking Height | 85mm |

| Max. Milling depth | 2mm |

| Net Weight | 950kg |

| Overall Dimensions(L*W*H) | 2060*2500*1360mm |

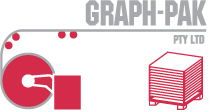

GALAXY 2000e PERFECT BINDER

GALAXY 3000e is a fully automatic perfect binder with excellent cost/performance ratio,supplying the best solution for production of supreme quality books in short run,medium run.All main and important functions are adjustable via the color touch screen by servo motors. Applying years of experiences and technologies from the big binding lines, perfectly realize industrial book quality binding for

digital printing.

Options

1.Closed gluing system, automatic change between PUR and EVA book binding.

2.Premelt tank for EVA hotmelt glue.

Performance characteristics

- Industrial and heavy-duty design and frame to ensure professional book binding quality.

- Fully automated set-up through color touch screen.

- Easily operated by anyone in the bindery. Maximum cycle speed is 3000 books per hour.

- Easy handling due to direct feeding of the book block into a coated clamp.

- All book thickness related adjustments are made automatically in minutes.

- Separated spine- and side-gluing unit.

- Glue length adjusted automatically and according to the programmed product format.

- Supreme spine formation due to clamp-following heavy duty pressing station.

https://youtu.be/auuVI1h39Uw

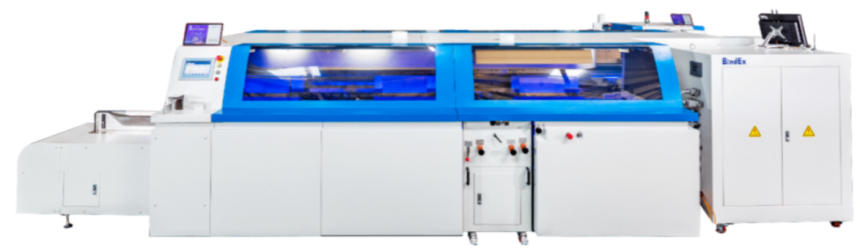

GALAXY MAX PERFECT BINDER

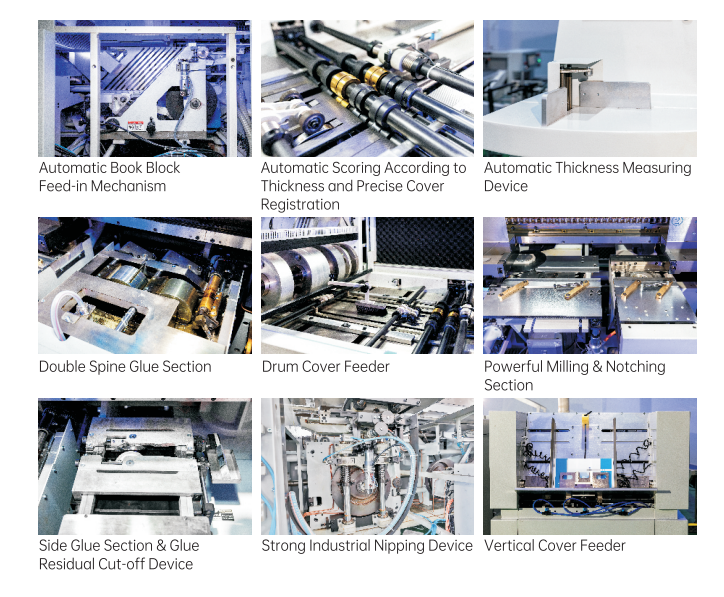

GALAXY MAX allows all adjustments to key positions to be done on the touch screen by means of servo motor control, an automatic book block infeeding mechanism is designed to replace the conventional manual book-feeding platform. The new design not only reduces labor intensity, but also allows the machine to integrate itself with book block preparation systems to form inline production.

Applying years of experiences and technologies from big binding lines, GALAXY MAX perfectly realized industrial book quality binding for digital printing/commercial printing/short run printing.

Technical Features

- Easy to use thanks to interactive user interface via touch screen.

- Industrial and heavy-duty design and frame to ensure professional book binding quality.

- Drum cover feeder realize non-stop continuous cover feeding; Reliable feeding for flapped covers; guides adjustments automatic according cover sizes.

- All book thickness related adjustments are made automatically within 8 minutes.

- Automatic book block infeeding mechanism is designed to replace the conventional manual book-feeding platform.

- Professional independent milling and notching section for superior spine preparation; Servo motor control of integrated notching and brush chip device.

- Movable spine-glue with double-rollers and side-gluing unit. The difference between GALAXY MAX and GALAXY MAX PRO:

- GALAXY MAX: Automatic glue cut-off.

- GALAXY MAX PRO: Glue unit with full servo control: Glue roller heights, scraper roller height adjustment automatic, Glue wiper opening and closing and timing controlled by servo motors .

- A movable glue premelting unit. Ensure uninterrupted supply of glue during production.

- Heavy duty double cam mechanism for superior spine nipping quality.

- Automatic book collecting section, to ensure high quality book spine formation.

Options

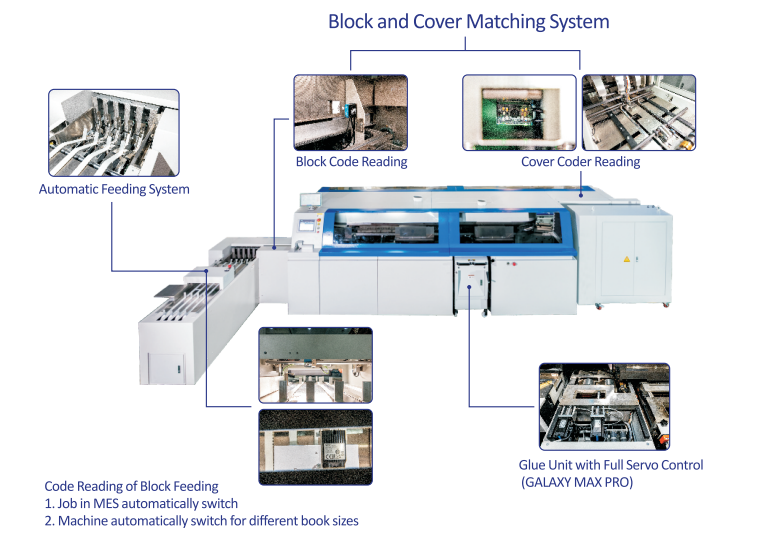

1. Book block and cover matching detection system

-Match the bar code on the cover and the block.

2. Automatic format change system by barcode/QRcode

-Through the recognition of the book block bar code by the reader, the book size is automatically obtained and the format is automatically changed.

3. BindEx Clound Digital Factory Solution

4. automatic feeding system for book blocks with digitally printed loose sheets

5. Connect with BOSSA50e or JAZZ 100e series three knife trimmer

6. Connect with PYGD450A or Y450e gathering machine

7. closed gluing system for PUR, automatic change between PUR and EVA book binding

Automatic-Adjustment-Points

| POSITION | GALAXY MAX | GALAXY MAX PRO |

| Book Clamp Opening | √ | √ |

| Book Speed-up Unit | √ | √ |

| Infeeding Channel | √ | √ |

| Book Infeeding Platform | √ | √ |

| Spine Milling Section (Width and Height | √ | √ |

| Notching Section (Width and Height | √ | √ |

| Side Glue Section | √ | √ |

| Cover Feeder Stack | √ | √ |

| Scoring Wheels | √ | √ |

| Cover Transport Section | √ | √ |

| Nipping Section (Width and Height) | √ | √ |

| Book Delivery Channel | √ | √ |

| Glue Roller Height | - | √ |

| Scraper Roller Height | - | √ |

| Glue Wiper Opening Distance | - | √ |

| Glue Wiper Opening and Closing | - | √ |

SPECIFICATION

| Book clamp number | 6 |

| Max. Mechanical Speed | 2500 c/h |

| Max. Binding Size | 400mm×320mm |

| Min. Binding Size | 150mm×105mm |

| Max. Cover Size | 400mm×630mm |

| Min. Cover Size | 150mm×226mm |

| Binding thickness | 3mm-50mm |

| Main power | 24kw |

| Net weight | 6000kg |

| Overall dimensions (L×W×H) | 6750mm×2200mm×1500mm |