NSK-ZERO

NSK-ZERO

Elevate your productivity with the unmatched quality and excellence!

Introducing the Fastest ZERO: An Innovative ZERO Hardware Engineered for the future! Revolutionary new concept in Automated, production-level finishing for packaging and display industry. The speed, and ease-of-use are features and solution designed for superior performance and precision.

Digital Converting Machine ZERO is the New solution in POS/POP display processing. With a maximum output of 300 sheets per hour and a continued focus on improving the software, ZERO provides the fastest all-digital production in the market today.

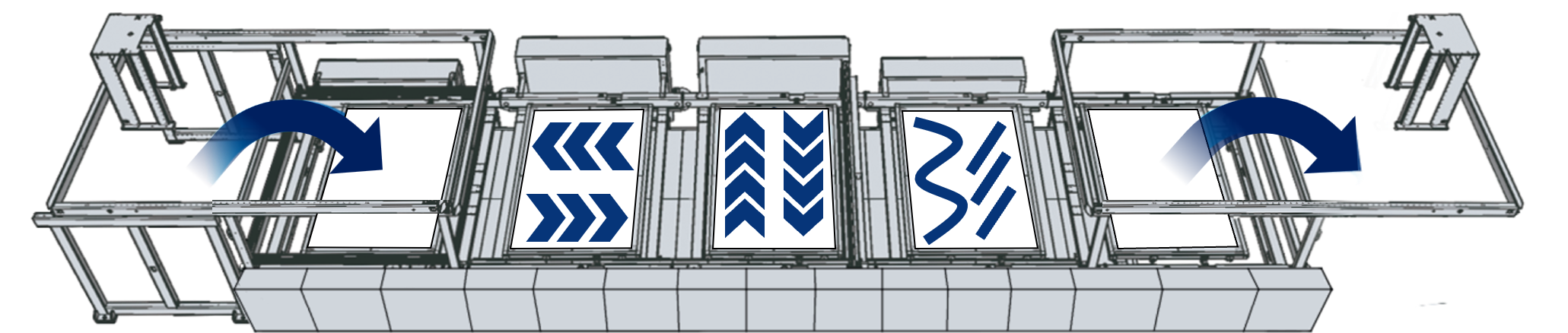

Separate tables work together simultaneously for faster processing. The Shape of a New Concept!

1. LOADING UNIT

When a job starts, the Loading Unit's pickup arm transports boards into the machine. The camera system checks the alignment of each sheet and adjusts for placement.

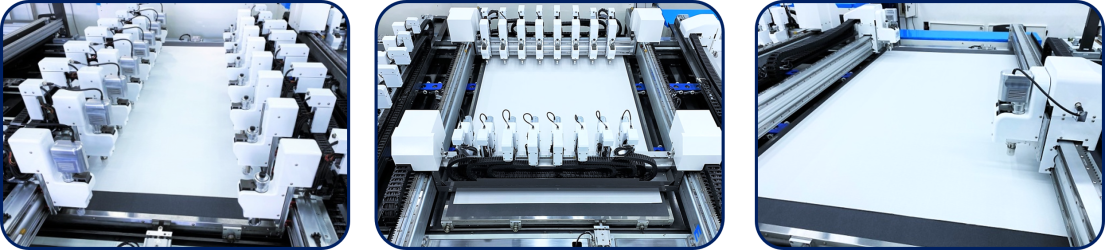

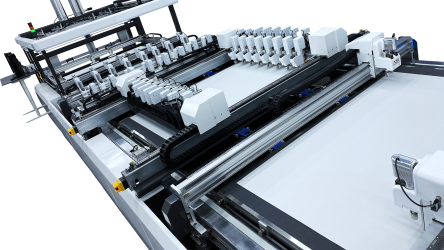

2. X STAGE

Horizontal cut and crease data is processed by up to 16 individual tools. All lines are processed at the same time to achieve faster production.

3. Y STAGE

Vertical line data is processed according to the data file. The tools move up and down across the table with high speed and precision.

4. FREE STAGE

All remaining line data is processed on the free stage. Dual twin heads cut and crease diagonal and curved lines for greater productivity.

5. UNLOAD UNIT

The Unloader Arm takes finished sheets and stacks them for easy removal. The Unloader's vacuum panel ensures that no pieces are left behind.

6. SHUTTLE TABLES

Materials are held in place by vacuum and move through the machine on revolving shuttle tables. The tables lock into place at each stage before processing begins.

XYF Stages Illustration